| General information | |

| Access mode | Physical access |

| Infrastructure name and acronym | Multiphase Atmospheric Experimental Simulation Chamber (CESAM) |

| Photos |

|

| Location | Créteil, France 48.789074, 2.443982 |

| Website | http://www.cesam.cnrs.fr/ |

| Legal name of organisation operating the infrastructure | Centre National de la Recherche Scientifique - Laboratoire Interuniversitaire des Systèmes Atmosphériques (CNRS-LISA) |

| Description of the infrastructure | |

| Brief general description of the infrastructure to which access is offered |

The CESAM platform consists of a combination of two chambers (CESAM chamber and CSA chamber) that can work both with gas or multiphase reacting mixtures involving gaseous trace species, organic particles, water droplets, mineral dust, soot and salts. It has been designed to perform studies on multiphase atmospheric processes under realistic conditions. The CESAM chamber is the largest atmospheric simulation chamber of the CESAM platform. It is dedicated to the study of multiphase atmospheric processes such as the formation of secondary aerosol or gaseous compounds in cloud-phase reactivity. It’s a 4.2 m3 stainless steel atmospheric simulation chamber, evacuable down to a few 10-7 atm and it is temperature controlled between +0°C and +60°C. It is equipped with high power xenon arc lamps which the artificial light source the more realistic to sun irradiation. Due to the very low level of electrostatic charges on its wall the aerosol lifetime in CESAM can be very long for submicron particle (up to 4 days) which enable the study of the ageing processes of secondary aerosol as well as their consequences on their properties. The scientific spectrum of CESAM chamber is nevertheless much larger than SOA studies as it is also possible to generate cloud events, to inject desert dust or soots, to seed with ionic aerosols and to perform photochemistry study. CESAM chamber is granted by CNRS as national instrument. The CSA chamber is an atmospheric simulation chamber dedicated to the atmospheric gas processes and spectrometry studies. It is a 1m3 pyrex reactor evacuable down to a few 10-2 mbars. It is equipped with artificial irradiation system which consist in 80 UV-lamps (centred at 360 nm and 420 nm) and 16 arc and Hg lamps (λ < 300 nm). The CSA is equipped with analytical devices for gas phase such asUV-Visible and Visible IBB-CEAS spectrometer, FTIR and PTR-Tof-MS (Kore ltd.) that enable atmospheric chemistry monitoring and cross-determination of compound absorptivities in both IR and UV-Visible spectral ranges withnumerous applications for remote sensing measurements. The CSA chamber is a perfect tool for intercalibration of IR/UV spectra and study the gas phase reactivity of organic and polyfunctional organic species (e.g nitrates). It is a complementary glass chamber which offers a good alternative to stainless steel walls. The CESAM platform is equipped with a comprehensive set of analytical instruments and benefits from the instrumental environment dedicated to atmospheric chemistry provided by LISA: PTR-ToF-MS (Kore ltd.), NOx Analyser, O3 Analyser, SO2 Analyser, External CRDS (Picarro 2302), Sorbent cartridges + GC-MS, Automatic GC- FID, in-situ FTIR, Hygrometer, Supercritical Fluid Extraction- GC-MS, EC/OC (Sunset), Hygroscopy Tandem DMA, Analytical Electron microscopes, SMPS, Light-scattering aerosol, CAPS-Pmex Aerodyne, CAPS-Pmex Aerodyne, Nephelometre (TSI 3596), Aethalometer (AE-31 Magee Scientific), Spectroradiometer LiCOR 1800.

|

| Services currently offered by the infrastructure and its research environment |

The services offered by the infrastructure include: - Access to the full equipment of the CESAM platform to which can be added when possible the equipment of the Pegasus field facility as well as the clean rooms, two electron microscopes (TEM, SEM) |

| Modalities of access and support offered under EUROCHAMP-2020 | |

| Typical duration of work |

Between 1 and 3 weeks. A typical work includes 2-3 days to carefully prepare the experiments (latest protocol adjustment, connection of potential external instruments, and training on the use of the chamber and the main devices), then 10 days of experiments (1 experiments/day), then 1-2 days for debriefing and base data formatting, saving, and distributing among the users. |

| Community/user type served |

The CESAM platform is mainly used for research project (so academic sector) nevertheless we have had experiment conducted with companies (self-cleaning material) and for protocol testing from governmental agency (INERIS). |

| Scientific and technical support offered | Training for the use of the infrastructure and the data treatment is offered. Depending on the degree of expertise of the guest, a data analysis of level 1 (FTIR, PTR-ToF-MS, electronic microscopy and mass spectra) can be proposed to users. In addition, pre-modelling assistance for the definition of experimental conditions is offered to all groups. |

| Logistic and administrative support offered | Administrative support for ordering chemicals and consumables, logistic support for the management of chemicals, including gases (ordering, conservation, provision), as well as centralised logistic support for liquid nitrogen provision. |

| Person in charge of access provision at the infrastructure | Dr. Mathieu Cazaunau, Research Engineer at CNRS, mathieu.cazaunau@lisa.u-pec.fr |

| Extended technical information - CESAM installation - |

|

| Physical description | The CESAM chamber is made of 304L stainless steel. Volume : 4177 litres Diameter : ca. 1.8 m (without port extension) Height : ca. 2.3 m Projected horizontal surface area : 2.3m² Surface-to-volume ratio : 4.3 m-1 Limit vacuum : 10-4 mbar RH range: 0-100% |

| Mechanical description |  |

| Mechanical description (CAD file) | CAD description in STP format (build by E. Pangui /CNRS-LISA) : CESAM-CADdescription_by_EPangui.zip Note : STP stands for STandard for the Exchange of Product. STP is a file extension for a 3-D graphic file used by CAD software. STP files are used to store 3D image data in an ASCII format, following the standards defined in ISO 10303-21 : Clear Text Encoding of the Exchange Structure. STP files can be opened by CATIA (Computer Aided Three Dimensional Interactive Application), a commercial CAD software suite created by Dassault Systemes and marketed by IBM but freevare viewers are also available |

| Irradiation spectra | Shape of the CESAM irradiation spectrum (provided by 3 high pressure xenon arc lamp of 4kW each ) compared with the solar spectrum a ground level (noon, 45° lat north, 21/06 from TUV NCAR) - Valide for experiment carried out from 2006 to 2016 included (adapted from Wang et al, 2011).   Shape of the CESAM irradiation spectrum (provided by 3 high pressure xenon arc lamps each operated at 6.5 kW ) compared with the solar spectrum a ground level (noon, 45° lat north, 21/06 from TUV NCAR) - Valide for experiment from 2017 on. (mesurement from Dr. M. Cazaunau /CNRS-LISA) |

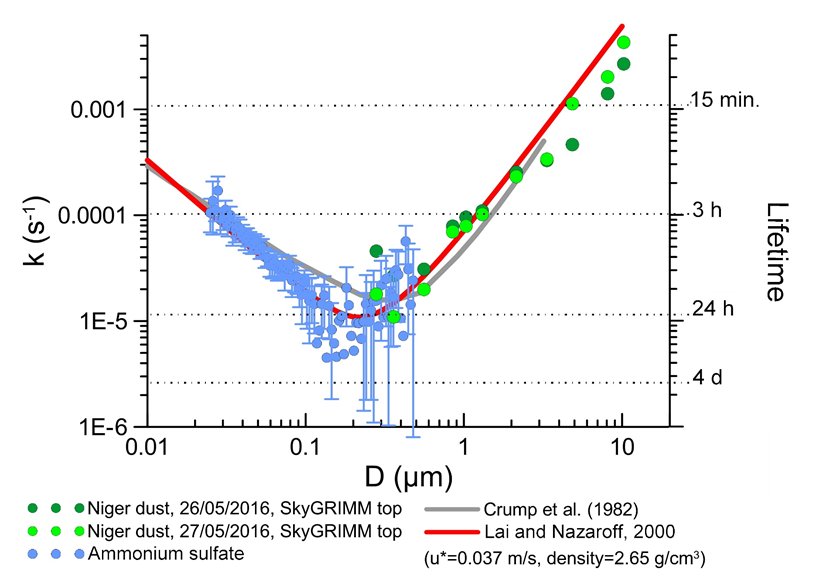

| Size dependent aerosol loss / lifetime |  Note : Adapted from Housni Lamkaddam's PhD thesis and Dr. Claudia Di Biagio work Note : Adapted from Housni Lamkaddam's PhD thesis and Dr. Claudia Di Biagio work |

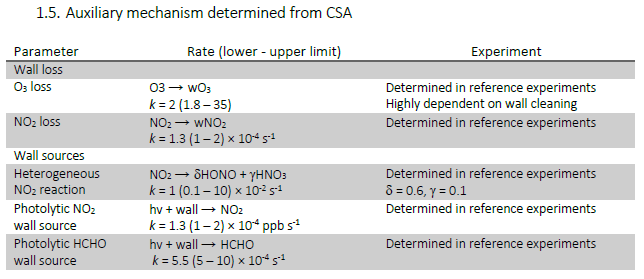

| Auxiliary mechanism | From Wang et al, 2011 - to be updated

Reactions constants Note NO2 → NO2_Wall 2.2.10-3 s-1 Indicative value only NO2_Wall → NO2 1.0.10-1 s-1 Indicative value only NO2 D NO2_Wall 46 Fast equilibrium : only the ratio k5/k-6 was determining NO2_Wall → α NO + β HONO 2.0.10-3 s-1 α = 0.34 and β = 0.07 NO2_Wall + hv → δ NO + γ HONO 1.4.10-2 s-1 δ = 0.51 and γ = 0.10 O3 → O3_Wall 3.0.10-4 s-1 |

| Description paper | Wang, J., Doussin, J. F., Perrier, S., Perraudin, E., Katrib, Y., Pangui, E., and Picquet-Varrault, B.: Design of a new multi-phase experimental simulation chamber for atmospheric photosmog, aerosol and cloud chemistry research, Atmos. Meas. Tech., 4, 2465-2494, https://doi.org/10.5194/amt-4-2465-2011, 2011. |

| Extended technical information - CSA installation - |

|

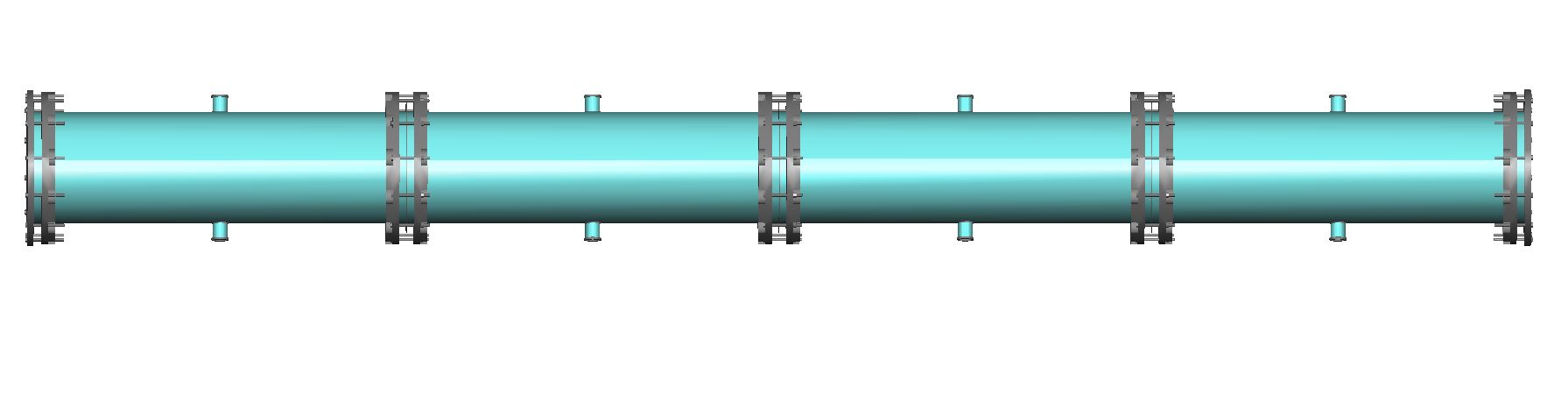

| Physical description | The CSA chamber is a cylindrical pyrex reactor. Volume: 977 L Diameter: 45 cm Length: 600 cm Surface-to volume ratio: 9 m-1 Limit vacuum: 10-2 mbar |

| Mechanical description |  |

| Mechanical description (CAD file) | CAD description in STP format (build by E. Pangui /CNRS-LISA) : CSA-CADdescription_by_EPangui.zip Note : STP stands for STandard for the Exchange of Product. STP is a file extension for a 3-D graphic file used by CAD software. STP files are used to store 3D image data in an ASCII format, following the standards defined in ISO 10303-21 : Clear Text Encoding of the Exchange Structure. STP files can be opened by CATIA (Computer Aided Three Dimensional Interactive Application), a commercial CAD software suite created by Dassault Systemes and marketed by IBM but freevare viewers are also available |

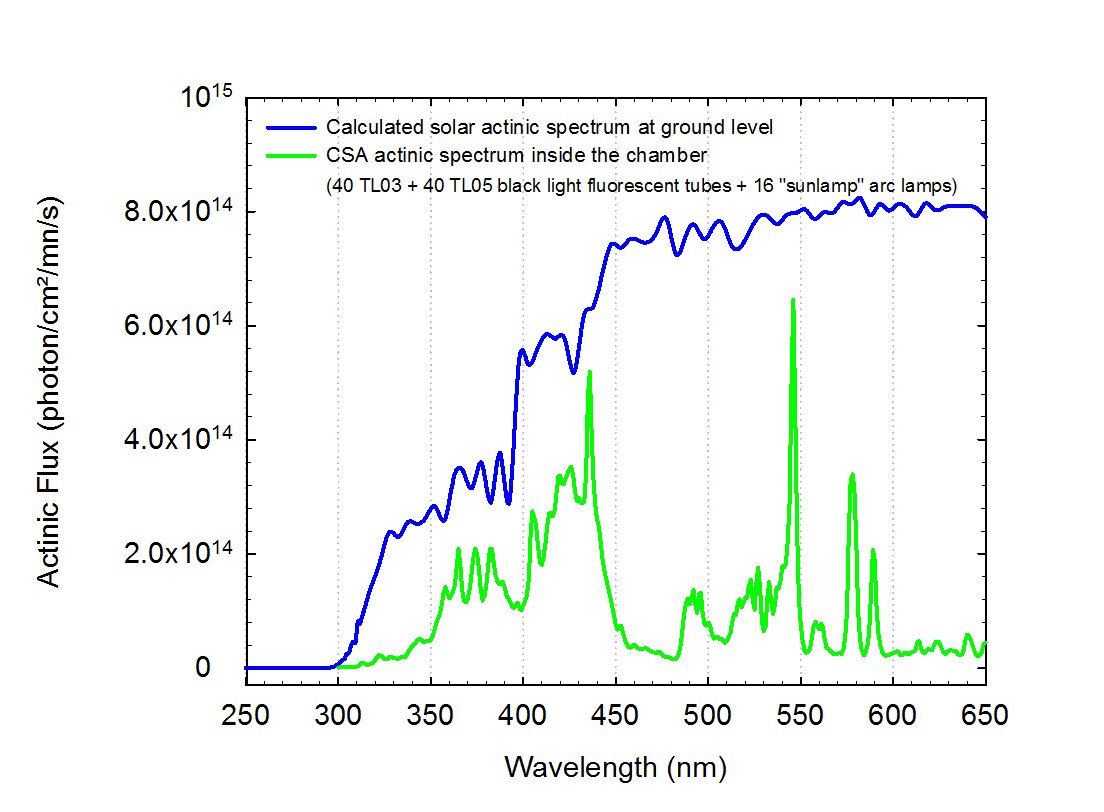

| Irradiation spectra |  |

| Auxiliary mechanism |  |

| Description paper | Doussin, J. F., Ritz, D., DurandJolibois, R., Monod, A., and Carlier, P.: Design of an environmental chamber for the study of atmospheric chemistry: New developments in the analytical device, Analusis, 25, 236-242, 1997. link |