| General information | |

| Access mode | Physical access |

| Infrastructure name and acronym | EUropean PHOtoREactor (EUPHORE) |

| Photos |  |

| Location | Paterna (Valencia), Spain 39.55160192861979, -0.46152786966385395 |

| Website | http://www.ceam.es/WWWEUPHORE/home.htm |

| Legal name of organisation operating the infrastructure | Fundación Centro de Estudios Ambientales del Mediterráneo (CEAM) |

| Description of the infrastructure | |

| Brief general description of the infrastructure to which access is offered |

EUPHORE is one of the major international outdoor simulation chamber facilities and it is used to research atmospheric chemical processes. Its characteristics allow the simulation of these processes under near-real conditions thanks to its large size and to the use of natural light. The installation has two twin outdoor atmospheric simulation chambers. Each chamber consists of a half spherical transparent bag of fluorine-ethene-propene (FEP) with a volume of about 200 m3, making it one of the biggest outdoor simulation chambers in the world. EUPHORE chambers are equipped with a large number of analytical instruments for measuring physical parameters as well as a diverse range of biogenic and anthropogenic compounds and its intermediates and products in both the gas and the particle phases. |

| Services currently offered by the infrastructure and its research environment |

- Installation of a large number of external high-level instrumentation can be accommodated at the same time, thus allowing extensive intercomparison/scientific campaigns to be performed. |

| Modalities of access and support offered under EUROCHAMP-2020 | |

| Typical duration of work |

Between 1 and 4 weeks. Tipically, the campaign starts with the installation of external instruments, which may take 1-2 days, latest discussions and advices to better adapt the experiements and the latest adjustments and chamber conditioning, then 10 days of experiments (1 experiments/day), then 1-2 days for debriefing and base data formatting, saving, and distributing among the users. |

| Community/user type served |

Scientific projects as well as studies contracted by enterprises are welcome. EUPHORE has a vast experience in research oriented projects while in the last years, many companies have used the chambers to test new instrumentation and to carry out studies their products before being released to the market (e.g. pesticides, photocatalytic materials, etc). |

| Scientific and technical support offered | The EUPHORE team offers support for planning the experiments. Depending on the grade of expertise of the users, EUPHORE staff gives advice on the design of the experiments, for flexible adaptation of the experimental schedule during the measurement campaigns and for data analysis: Equally, data collected with our instrumentation can be analysed by our staff or by the users, which are provided with both the raw and the treated data, when requested. |

| Logistic and administrative support offered | - Administrative support for ordering chemicals and consumables - Support for the management of chemicals, including gases (ordering, conservation, provision) and gases required for the functioning of the external instruments - Support for hotel booking/accomodation during the stay |

| Person in charge of access provision at the infrastructure | Dr. Amalia Muñoz, Senior Researcher, EUPHORE facility coordinator amalia@ceam.es |

| Extended technical information | |

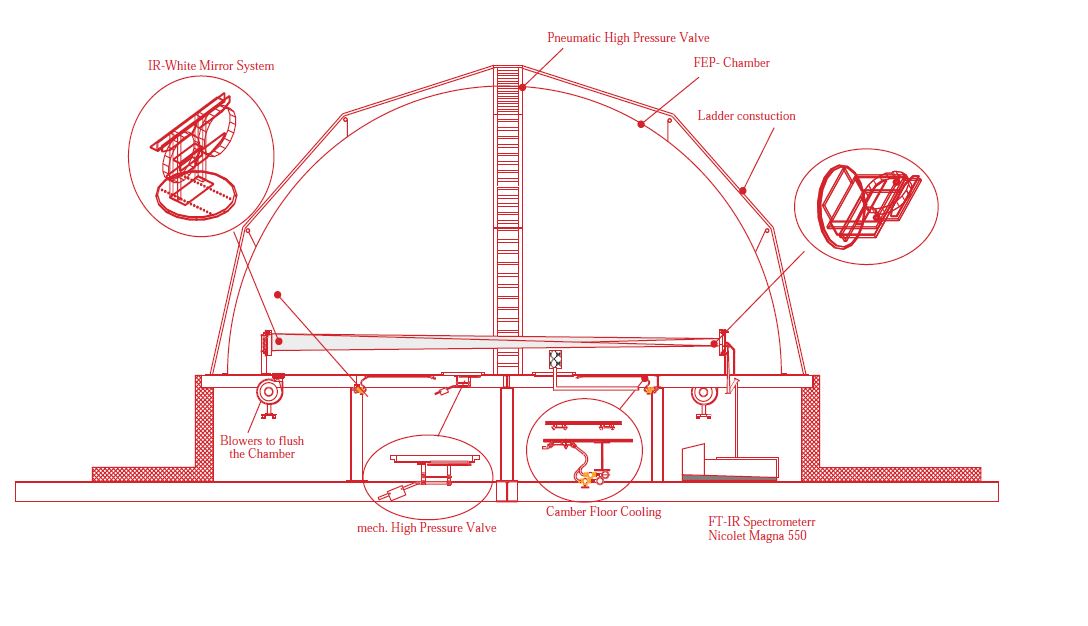

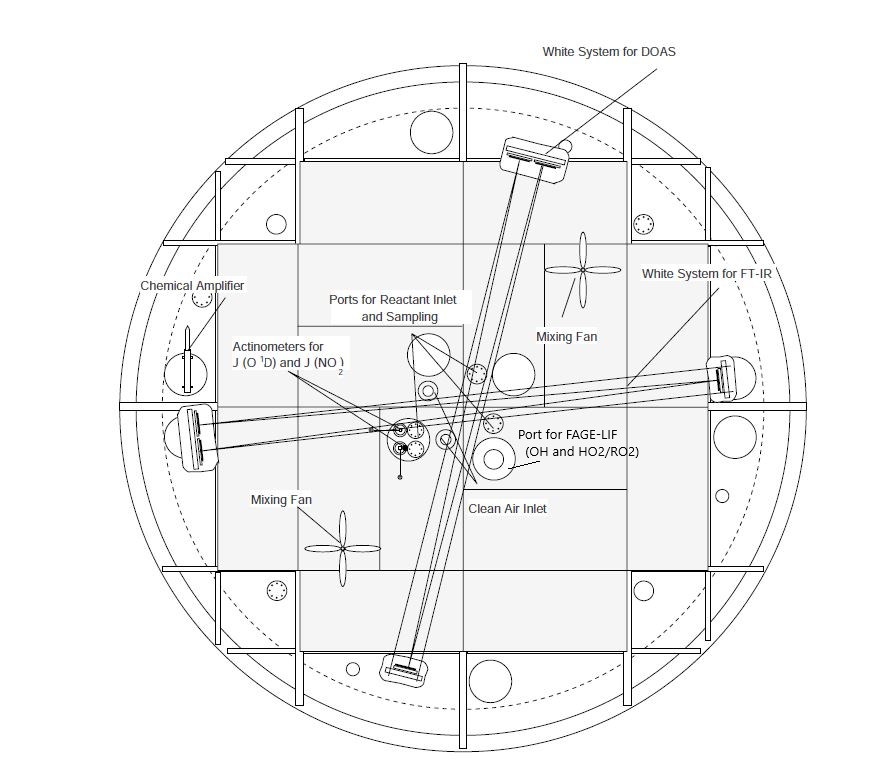

| Physical description | EUPHORE consists of two identical half-spherical FEP (fluorineethene-propene) foil chambers with volumes of approximately 200 m3. A retractable steel housing surrounds the chamber and is used to control the time of exposure to sunlight. The chamber is filled to atmospheric pressure with purified dry air and the temperature and humidity inside the chamber are measured continuously using PT-100 thermocouples and a dew-point mirror system. S/V ratio: S/V = 1 m-1 Dimensions: - 2 hemispherical chambers made of FEP foil. - Volume: 200m3 each - Diameter: 9 m Temperature range: Ambient temperature (+ 0-6 K)Pressure range: (ambient pressure + 2 mbar) 990 - 1020 mbar RH range: 0 - 60% if FTIR is used, up to 90% otherwise Geographic position: longitude = -0.5°, latitude = 39.5°N Projected surface area: 63.6m2 (horizontal surface area) |

| Mechanical description |

Each chamber consists of a half-spherical Teflon bag with a volume of ca 200m3. The chambers are made of FEP (fluorine-ethene-propene) foil with a thickness of 0.127 mm, with transmission of more than 80% in the wavelength range between 280 and 640 nm. The chamber consists of 32 welded segments of the foil. The Teflon bags are suspended from a central point inside the frame of ladders. The chambers are protected against atmospheric influences by two half-sphere shaped protective houses. Each chamber floor consists of 32 symmetrically arranged aluminium panels covered with FEP foil. The chamber bags are connected to the floors with the help of specially designed clamps. An integrated rubber cord is used as a seal between the bag and the chamber floor. Located on each chamber floor are 10 large circular openings (diameter of 0.6 m) and 20 smaller openings (diameter of 0.2 m), each closed with aluminium flanges, for accessing the chamber, for installing instrumentation in the chambers and as sampling ports. To compensate heating of the chamber by solar radiation, the chamber floor panels are cooled by a refrigerating system. In order to stabilize the chambers against wind, the pressure in the chambers has to be slightly higher than the outside pressure. To protect the foil different safety precautions are installed. The pressure in the chambers is typically regulated within a range 100 to 200 Pa above the outside pressure. To clean the chambers after an experiment the chamber valve can be opened while air is flushed through the chamber. The inlet and outlet ports and other accessories, like mixing fans, analytical systems, mechanical excess pressure valves, are located on the floor in order that the chamber surface is free for light entry. Integrated into the flanges are ports for the input of reactants and the sampling lines for the different analytical instruments.   |

| Auxiliary mechanism |  |

| Irradiation spectra | Natural sunlight. Photolysis frequencies calculated from actinic flux measured inside the chamber. |

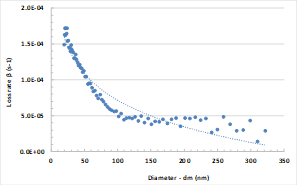

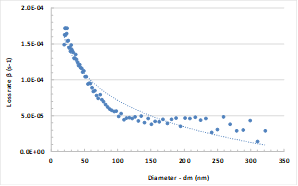

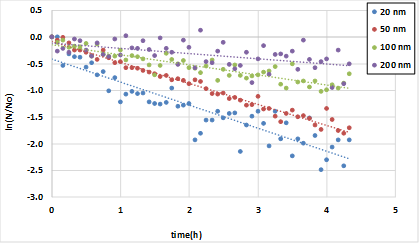

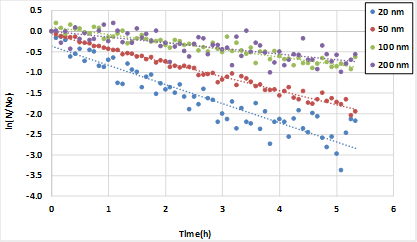

| Aerosol lifetime | Particle wall losses in the 200 m3 Teflon EUPHORE chamber have been characterized using a number of replicates of inorganic seed particles at 50% RH, with the chamber mixing and at different constant inflows: 0.03, 0.04 and 0.06 m3 min-1, respectively (continuously flow added to chamber for compensating sampling systems and small leaks). Seed wall loss experiments have been conducted using polydisperse (NH4)2SO4 particles, added during 10 min, and wall loss corrections from SOA experiments have been conducted using and correcting for coagulation losses following Wang et al. (2018a). Particulate data have been measured using a SMPS system with a long DMA 3081, a CPC 3775 low flow and, working in the 14 - 685 nm range. Submicronic ammonium sulphate particle were generated in small number to minimized coagulation The Figure 1 shows the corrected wall loss profiles for the 200 m3 EUPHORE chamber determined over 2 different inflows (diution: air added to compensate sampling) . The particle wall-loss rate constants, kc(Dp), were derived based on the model used by Nah et al. (2017), assuming that only two processes take place: particle wall loss and coagulation and the apparent wall loss, ka(Dp), was calculated from a first order loss fitted to size-resolved SMPS data.   Figure 1: The particle wall-loss rate constants were derived based on SMPS measurements from experiments with only ammonium sulfate particles. a) chamber dilution 7 x 10-6 s-1 calculated by SF6 losses b) 1.12 x 10-5 s-1 Moreover, the particle wall loss rate constants in Eq. (1) for selected particle size 20, 50, 100, and 200 nm (β20 nm, β50 nm, β100 nm, and β200 nm) were determined. Smaller particles deposit faster onto the chamber walls. The logarithmic relative number concentration as a function of time of 20, 50, 100, and 200 nm polydisperse ammonium sulfate aerosols have been also determined (see Figure 2).

The equations for the linear fittings for inflow 0.03 m3 min-1 are: ln(N/N0) = −0.4321t – 0.4123 (20nm), ln(N/N0) = −0.3951t –0.0741 (50 nm), ln(N/N0) = −0.1899t -0.1375 (100 nm) and, ln(N/N0) = −0.0971t −0.1138 (200 nm)  The equations for the linear fittings for inflow 0.04 m3 min-1 are: ln(N/N0) = −0.4622t – 0.3699 (20nm), ln(N/N0) = −0.3409t – 0.0785 (50 nm), ln(N/N0) = −0.1816t + 0.1044 (100 nm) and, ln(N/N0) = −0.1375t −0.0030 (200 nm) Figure 2: Logarithmic relative number concentration as a function of time of 20, 50, 100, and 200 nm polydisperse ammonium sulfate aerosols plot. Finally, we also calculate de average RSD value for each logarithmic relative number concentration decay with values as 8%, and 10% for each chamber dilution compensation (7 x 10-6 s-1 and 1.12 x 10-5 s-1 |

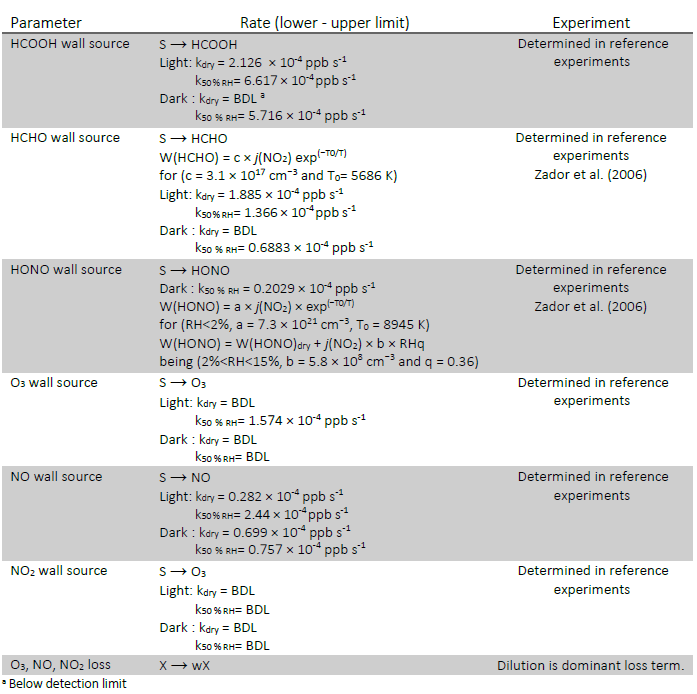

| Description paper | Bloss, C., V. Wagner, A. Bonzanini, M. E. Jenkin, K. Wirtz, M. Martin-Reviejo and M. J. Pilling: (2005a) Evaluation of detailed aromatic mechanisms (MCMv3 and MCMv3.1) against environmental chamber data, Atmospheric Chemistry and Physics 5: 623-639 Bloss, C., V. Wagner, M. E. Jenkin, R. Volkamer, W. J. Bloss, J. D. Lee, D. E. Heard, K. Wirtz, M. Martin-Reviejo, G. Rea, J. C. Wenger and M. J. Pilling: (2005b) Developement of a detailed chemical mechanism (MCMv3.1) for the atmospheric oxidation of aromatic hydrocarbons, Atmospheric Chemistry and Physics 5: 641-664 Zador, J., V. Wagner, K. Wirtz and M.J. Pilling (2005) Quantitative assessment of uncertainties for a model of tropospheric ethene oxidation using the European Photoreactor (EUPHORE), Atmos. Env. 39, 2805–2817 Zador, J., T. Turanyi, K. Wirtz and M.J. Pilling (2006) Measurement and investigation of chamber radical sources in the European Photoreactor (EUPHORE), J. Atmos. Chem. 55, 147–166 |