| General information | |

| Access mode | Physical access |

| Infrastructure name and acronym | FORTH Atmospheric Simulation Chamber (FORTH-ASC) |

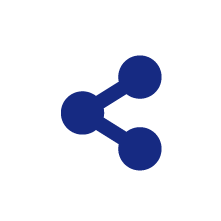

| Photos |  |

| Location | 38.297504 N; 21.808678 E Patras, Greece |

| Website | Laqs.iceht.forth.gr |

| Legal name of organisation operating the infrastructure | Foundation for Research and Technology Hellas, Institute of Chemical Engineering Sciences (FORTH/ICEHT) |

| Description of the infrastructure | |

| Brief general description of the infrastructure to which access is offered |

Indoor chamber: 103 Teflon reactor in 30m3 temperature controlled UV-equipped room. plus two 2m3 Teflon reactors inside UV-equipped enclosure. |

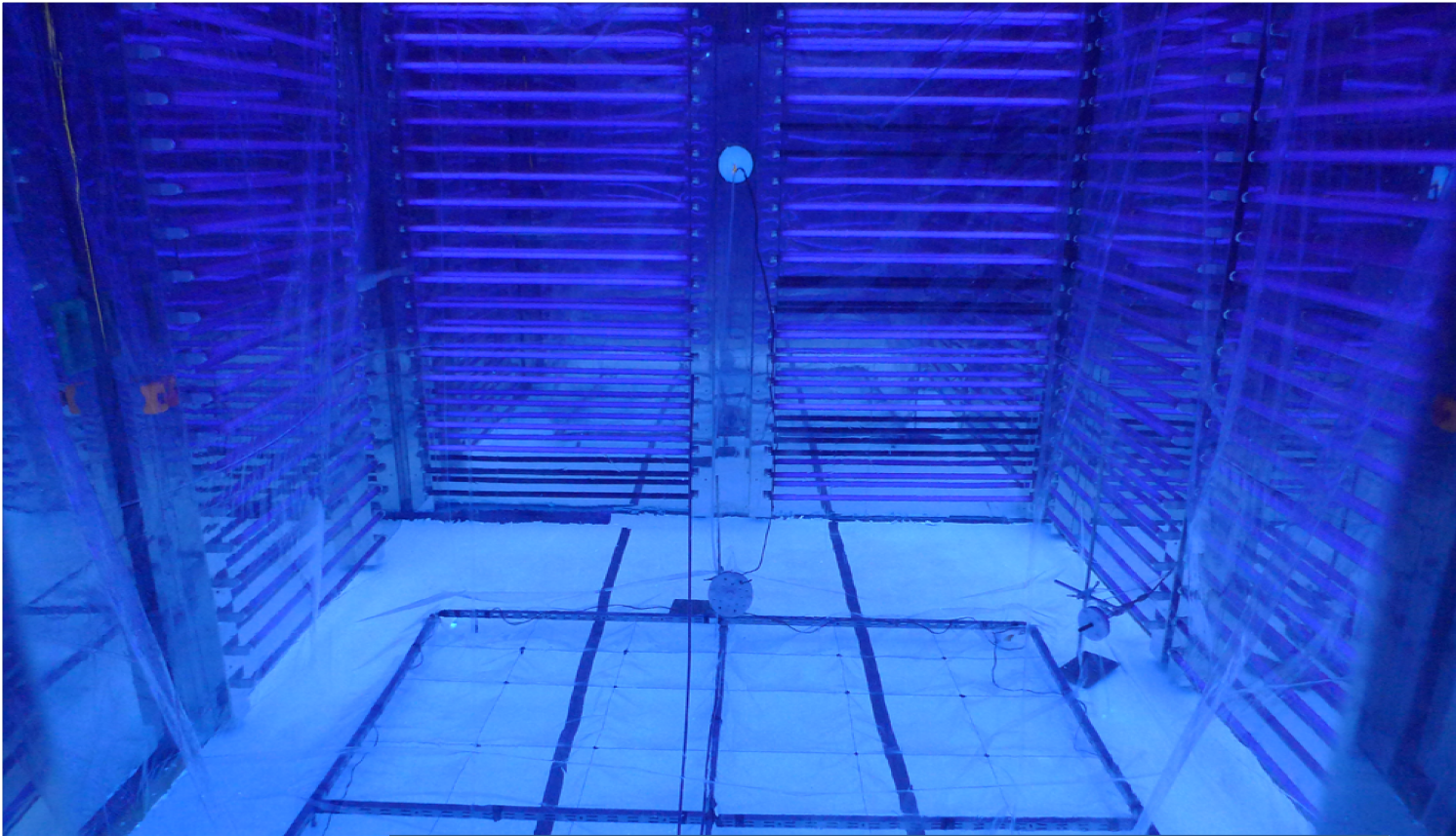

| Services currently offered by the infrastructure and its research environment |

- Testing/intercomparisons of new instruments. |

| Modalities of access and support offered under EUROCHAMP-2020 | |

| Typical duration of work |

Between 2 and 4 weeks. A typical campaign includes 2-3 days of preparing the chamber for the experiments (e.g. connection of external instruments, testing), then 10-15 days of experiments (one experiment per day) and finally 2-3 days of data sharing and preliminary analysis and planning of the rest of the analysis and synthesis. |

| Community/user type served |

The FORTH chamber has been used until now mainly by the academic sector. However, it is available for both the private sector and government. |

| Scientific and technical support offered | The FORTH team (depending on user needs) can either perform or train the user to perform all activities. In the one unit of access we include the: - Preparation of chamber (cleaning, testing, characterization) - Experiment (design is quite flexible, all instruments of LAQS are available) - Correction of raw data [HR-AMS corrections for collection efficiency, wall loss corrections for particles, quality assurance/quality control of data] |

| Logistic and administrative support offered | Assistance with transport and installation of additional instrumentation to the site is offered. Troubleshooting and repairs can be provided. The institute offers assistance by providing local accommodations. |

| Person in charge of access provision at the infrastructure | Dr. Spyros Pandis, spyros[at]chemeng.upatras.gr |

| Extended technical information | |

| Physical description |

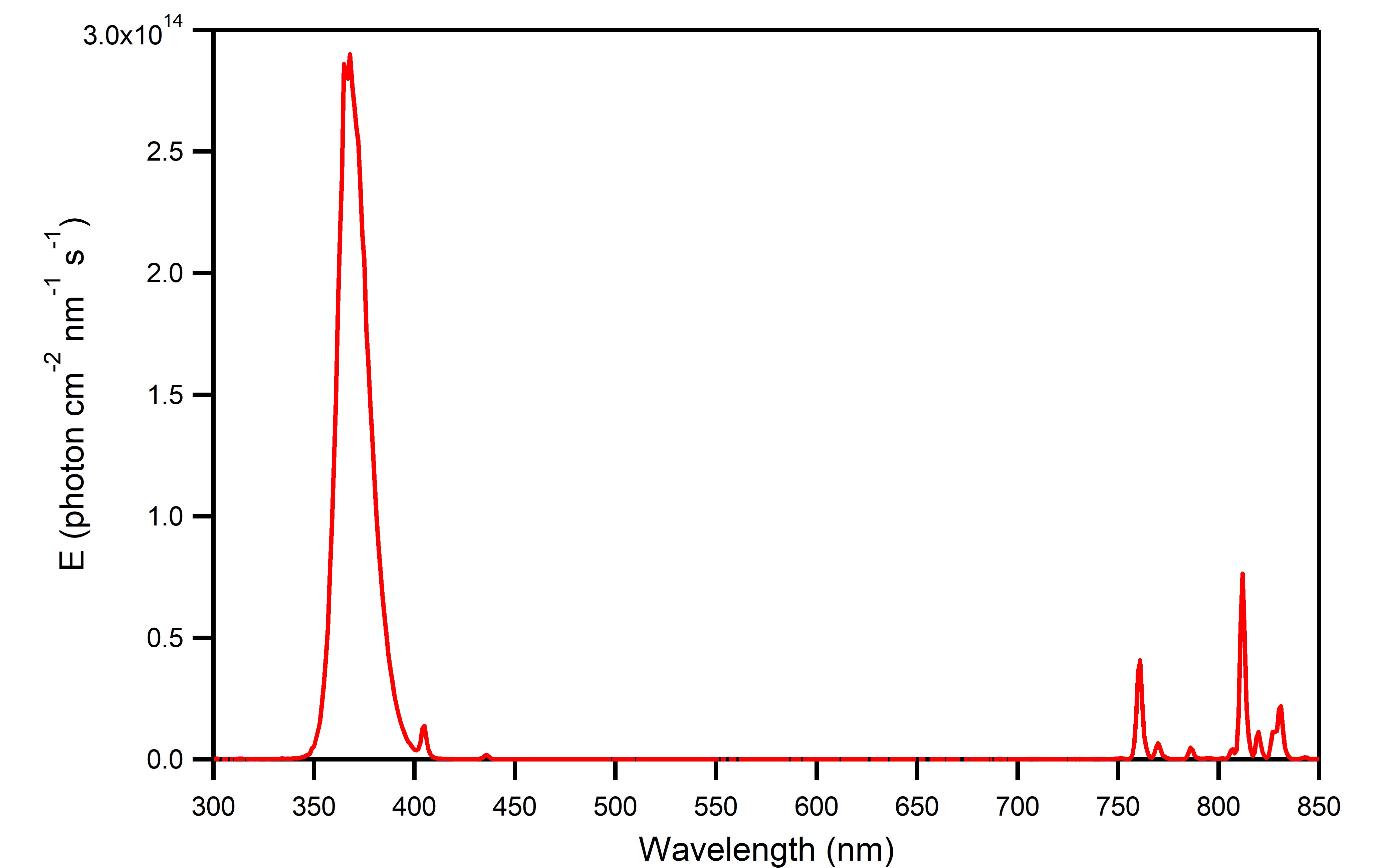

The main FORTH-ASC chamber is a 10 m3 Teflon reactor inside a 30 m3 temperature-controlled UV-equipped room. The dimensions of the reactor are approximately 2.2 x 2.2 x 2 m. The reactor operates at a little above atmospheric pressure. S/V ratio: 2.7 m-1 Irradiation JNO2: 0.59 hr-1 (all lights on) or 0.4 hr-1 (2/3 of the lights on) or 0.2 hr-1 (1/3 of the lights on) Temperature range: 15-40° C RH range: <5% - 90% Projected surface area: 4-5 m2 |

| Mechanical description | Teflon reactor suspended inside a 30 m3 room with polished aluminum covered walls. The vertical walls are covered with black lights |

| Irradiation spectra |  |

| Size dependent aerosol loss/lifetime |

10-20 hr for 0.1-2 μm particles (defined as in 1/k, where k is the particle wall loss rate constant to the walls) |

| Auxiliary mechanism | |

| Description paper |

Information about the chamber can be found in the following publications:

- Kostenidou E., C. Kaltsonoudis, M. Tsiflikiotou, E. Louvaris, L. M. Russell, and S. N. Pandis (2013) Burning of olive trees : a major organic aerosol source in the Mediterranean, Atmos. Chem. Phys., 13, 8797-8811.

- Kaltsonoudis, C., E. Kostenidou, E. Louvaris, M. Psichoudaki, E. Tsiligiannis, K. Florou, A. Liangou, and S. N. Pandis (2017) Characterization of fresh and aged organic aerosol emissions from meat charbroiling, Atmos. Chem. Phys., 17, 7143-7155.

- Louvaris, E. E., E. Karnezi, E. Kostenidou, C. Kaltsonoudis, and S. N. Pandis (2017) Estimation of the volatility distribution of organic aerosol combining thermodenuder and isothermal dilution measurements, Atmos. Meas. Tech., 10, 3909-3918. |